Liquid Paints and Coatings Market Manufacturers & Suppliers Company Analysis 2026-2035

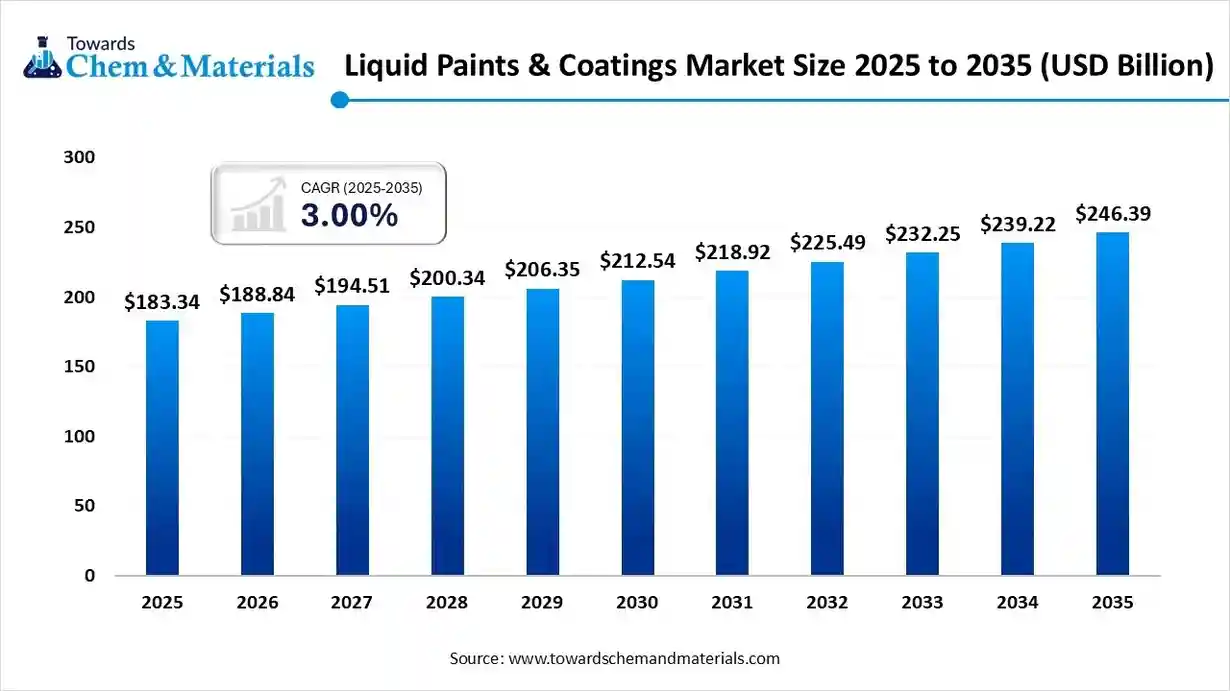

According to Towards Chemical and Materials Consulting, the global liquid paints and coatings market size was valued at USD 183.34 billion in 2025 and is expected to hit around USD 246.39 billion by 2035 at a CAGR of 3% from 2026 to 2035.

Ottawa, Dec. 18, 2025 (GLOBE NEWSWIRE) -- The global liquid paints & coatings market size is calculated at USD 183.34 billion in 2025 and is predicted to increase from USD 188.84 billion in 2026 and is projected to reach around USD 246.39 billion by 2035, The market is expanding at a CAGR of 3.00% between 2026 and 2035. Rising demand for durable, eco-friendly, and high-performance surface protection solutions in the construction and automotive sectors is driving the growth of the liquid paints and coatings market. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/6062

What are Liquid Paints & Coatings?

The liquid paints and coatings market is expanding as industries increasingly rely on advanced surface protection and aesthetic solutions across construction, automotive and industrial sectors. Growing emphasis on eco-friendly, low-VOC, and high-performance formulations, such as water-based and UV curable systems, is reshaping product development, supported by technological advancements and stricter environmental regulations. Demands are further strengthened by rising infrastructure activities, ongoing innovations in functional coatings, and the strategic efforts of major manufacturers to enhance product quality and sustainability.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Liquid Paints and Coatings Market Report Highlights

- Asia Pacific dominated the liquid paints & coatings market in 2025.

- North America is expected to grow at the fastest rate in the market between 2025 and 2035.

- By type, the water-based coatings segment dominated the market in 2025.

- By type, the UV-curable coatings segment is projected to experience the highest growth rate in the market between 2025 and 2034.

- By resin type, the acrylic segment dominated the market in 2025.

- By resin type, the polyurethane segment is anticipated to grow with the highest CAGR in the market during the studied years.

- By application, the building and construction segment dominated the market in 2025.

- By application, the automotive and transportation segment is projected to expand rapidly in the market in the coming years.

- By substrate, the metal segment dominated the market in 2025.

- By substrate, the composites segment is set to experience the fastest rate of market growth from 2025 to 2035.

Why Use a Liquid Coating?

This coating technology is prevalent for many reasons:

- It can be cured quickly, resulting in faster production cycles.

- It is cost-effective in the sense that the initial investment for the equipment is much less than for powder coating equipment (although liquid material is more expensive than powder and can’t be reclaimed).

- The coating can be used to finish parts containing sensitive materials, such as a metal cylinder with a rubber seal, because it does not require dramatically high temperatures to dry.

- It can be used to finish very large parts that are not able to fit into an oven or can’t be moved easily.

- A thin coating is achievable. It can routinely be applied as thin as 0.5 mil.

- It provides an automotive-quality finish (although this performance advantage over powder coatings has been narrowed greatly over the years).

Why Use a Powder Coating?

Users of powder coatings turn to this technology for a few specific reasons:

- As soon as the workpiece has cooled after curing, the part doesn’t require overly protective handling and immediately can be sent to downstream processes such as assembly or packaging.

- It is very durable. It is commonly used for outdoor applications ranging from outdoor furniture to agricultural.

- The process does not emit VOCs, which means local air quality regulations aren’t likely to be an issue for the manufacturer undertaking powder coating. Additionally, the material can be reclaimed, if the right equipment is installed, which limits the amount of waste material that has to be placed into the waste stream.

- Although it requires a large upfront investment, the long-term costs of applying powder are less than those for a liquid system. In some instances, the price of liquid material may be four times more.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6062

Paints And Coatings Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 188.84 Billion |

| Revenue forecast in 2035 | USD 246.39 Billion |

| Growth rate | CAGR of 3% from 2026 to 2035 |

| Base year for estimation | 2025 |

| Historical data | 2018 - 2025 |

| Forecast period | 2026 - 2035 |

| Quantitative units | Volume in kilotons, revenue in USD million/billion, and CAGR from 2026 to 2035 |

| Report coverage | Revenue forecast, volume forecast, competitive landscape, growth factors, and trends |

| Segments covered | By Type, By Resin Type, By Application, By Substrate, By Region |

| Regional scope | North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

| Country scope | U.S.; Canada; Mexico; Germany; UK; France; Italy; Spain; China; India; Japan; South Korea; Brazil; Argentina; Costa Rica; Saudi Arabia; South Africa. |

| Key companies profiled | Akzo Nobel N.V., PPG Industries, Inc, The Sherwin-Williams Company, BASF SE, Asian Paints, Axalta Coating Systems, Hempel A/S, Jotun A/S, Nippon Paint Holdings Co., Ltd., RPM International Inc. |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

What Are the Major Trends in the Liquid Paints & Coatings Market?

- Increasing use of artificial intelligence in formulation development to enhance performance prediction and colour stability.

- Integration of sensors into coatings for real-time monitoring of environmental and structural conditions.

- Development of bio-repulsive coatings that adapt to environmental changes.

- Transition from traditional protective coatings to multifunctional and adaptive surface technologies like self-healing and antimicrobial systems.

- Shift toward low-VOC, water –based, and sustainable formulation driven by environmental regulations and demand for greener products.

How Does AI Influence the Growth of the Liquid Paints & Coatings Industry in 2025?

Artificial intelligence supports the growth of the liquid paints and coatings industry in 2025 by accelerating formulation development, improving quality control, and enhancing manufacturing efficiency. Through data-driven prediction and optimisation, AI helps create more durable downtime. These advancements enable manufacturers to innovate faster and meet evolving performance and environmental expectations in the market.

Private Industry Investments for Liquid Paints & Coatings:

- JSW Paints A recent strategic acquisition by JSW in June 2025 saw it take over a majority stake in Akzo Nobel India, signaling major consolidation and increased competition in the market.

- The Carlyle Group This global private equity powerhouse has invested in coatings companies, including Axalta Coating Systems, demonstrating significant financial interest in performance and industrial coatings.

- Peak XV Partners (formerly Sequoia India) The firm provided early-stage venture funding to Indigo Paints, helping the company grow rapidly and eventually go public in the competitive Indian market.

- Hempel A global coatings supplier, Hempel operates as a private company (owned by the Hempel Foundation) that consistently invests in sustainable and protective coating solutions across various industries.

-

Benjamin Moore & Co. As a privately held subsidiary of Berkshire Hathaway, Benjamin Moore maintains a strong position in the architectural coatings market, focusing on premium products and a vast network of independent retailers.

Market Opportunity

What New Demand Arises from Eco-Friendly Coatings?

The shift toward environmentally friendly and sustainable products presents a strong opportunity for liquid paints and coatings manufacturers to develop water-based, low-VOC, and bio-based formulations that appeal to environmentally conscious consumers and comply with tightening environmental regulations, enhancing brand relevance and market appeal.

How Can Innovation in Surface Protection Drive Market Growth?

Expanding interest in advanced functionalities such as antimicrobial, self-cleaning, and smart coatings creates an opportunity for companies to differentiate offerings by addressing specialised performance needs in healthcare, construction, and industrial segments, opening new application areas and customer segments.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/6062

Liquid Paints and Coatings Market Segmentation Insights

Type Insights:

Why the Water-Based Coatings Segment Dominated the Liquid Paints & Coatings Market?

The water-based coatings segment dominated the market, reflecting how sustainability and environmental compliance are reshaping industry demand. Water-based formulations are increasingly preferred by both manufacturers and end users because they reduce harmful emissions and align with tighter environmental policies, while still providing strong performance in terms of application ease and finish quality.

The UV-curable segment is growing fastest in the market as advanced curing technologies gain traction for their efficiency and performance benefits. These coatings cure quickly under ultraviolet light without extensive heat, enabling faster production cycles and reduced energy consumption, which is especially valuable in high-speed industrial applications. UV-curable technologies also offer high-quality finishes with superior hardness and chemical resistance, attributes appreciated in electronics, packaging, and specialised industrial coatings.

Resin Type Insights:

Which Resin Type Segment Leads the Liquid Paints & Coatings Market?

The acrylic resin segment led the market because of its versatile performance across diverse coating needs. Acrylic resins deliver excellent adhesion, weather resistance, durability, and gloss, making them a preferred choice for decorative and protective applications alike. These properties help coatings maintain appearance and structural integrity over extended service life, whether used in building facades, automotive surfaces, or industrial equipment.

The broad applicability of acrylics across both interior and exterior environments increases their appeal to formulators and end-product manufacturers seeking reliable and adaptable resin systems.

The polyurethane resin segment is noted as the fastest-growing category due to its exceptional combination of flexibility, durability, and chemical resistance. Polyurethane systems are widely used where enhanced mechanical properties and long-lasting protective performance are required, such as in automotive, aerospace, and heavy industrial settings. Their ability to form resilient, weather-resistant films makes them attractive for coatings on substrates exposed to harsh environmental conditions.

Application Insights:

What Made the Building & Construction Segment Lead the Liquid Paints & Coatings Market?

The building & construction segment led the market because it consistently absorbs a large share of demand driven by continuous residential, commercial, and infrastructure development. This segment relies heavily on coatings for protection, durability, and aesthetic enhancement across walls, facades, wood, metal, flooring, and exterior structures.

The automotive & transportation segment is growing fastest in the market as manufacturers increasingly adopt high-performance coatings that enhance durability, corrosion resistance, and visual finish. This growth is supported by rising production of vehicles, ongoing upgrades in coating technology, and demand for materials that can withstand environmental stress, heat, abrasion, and chemicals. Automotive OEMs and aftermarket service providers rely on liquid coatings to ensure uniform appearance, smooth application, and long-lasting protection across vehicle bodies and components.

Substrate Insights:

Which Substrate Segment Leads the Liquid Paints & Coatings Market?

The metal substrate segment led the market because metal surfaces require strong protective layers to resist corrosion, degradation, and environmental wear. Liquid coatings offer a reliable solution for industries where metals are widely used, such as construction, automotive, marine, aerospace, and industrial machinery. These coatings enhance the lifespan of metal structures by providing resistance to moisture, chemicals, abrasion, and UV exposure while also delivering smooth and visually appealing finishes.

The composite substrate segment is considered one of the fastest-growing areas because industries are rapidly adopting lightweight and high-strength composite materials in automotive, aerospace, wind energy, marine, and industrial applications. As composites become more widely used, the demand for coatings that provide strong adhesion, smooth finishes, and long-lasting surface protection continues to rise. Liquid coatings formulated for composites help enhance durability, UV resistance, and environmental protection while maintaining the structural integrity of advanced composite materials.

➤ Contact Us: sales@towardschemandmaterials.com | ☎ +1 804 441 9344

Regional Insights

What Makes Asia Pacific Dominate in the Liquid Paints & Coatings Market?

The Asia Pacific region dominated the market, due to extensive construction and industrial activity, strong manufacturing bases, and growing demand from key sectors such as automotive, infrastructure, and consumer goods. Rapid urbanisation and expansion of residential and commercial projects in countries like India, Japan, and Southeast Asian economies are contributing to sustained consumption of both decorative and protective coatings.

China Liquid Paints & Coatings Market Trends

China plays a pivotal role within the Asia Pacific liquid paints and coatings market, driven by its vast construction sector and status as a global manufacturing powerhouse, particularly in automotive production and industrial output. Heavy residential construction, rapid urbanisation, and continued investment in infrastructure projects create strong demand for surface protection and finishing solutions.

Why Is North America the Growing Region in Liquid Paints & Coatings?

North America is expanding rapidly in the liquid paints and coatings market due to rising demand from the construction, aerospace, and industrial sectors, along with the growing adoption of advanced and sustainable coating technologies. Increasing renovation activities and stricter environmental standards are also encouraging the use of improved, low-emission formulations across the region.

U.S. Liquid Paints & Coatings Market Trends

The U.S. holds a dominant position in North America because of its strong manufacturing base, active infrastructure development, and high demand for both architectural and high-performance coatings. Continuous innovation in eco-friendly coating technologies further strengthens its role as the primary contributor to regional market growth.

Top Companies in the Liquid Paints & Coatings Market & Their Offerings:

- Asian Paints: Primarily a leader in decorative and architectural coatings across Asia.

- Axalta Coating Systems: Specializes in liquid transportation and performance coatings, especially for automotive use.

- BASF SE: Provides advanced liquid automotive and industrial coatings as part of its chemical offerings.

- Akzo Nobel N.V.: Global provider of liquid marine, protective, and decorative paints (brands like Dulux).

- The Sherwin-Williams Company: Manufactures and sells a wide variety of architectural and industrial paints globally.

- PPG Industries, Inc: Offers diverse liquid and powder coatings for construction, automotive, and industrial uses.

- Hempel A/S: Focuses strongly on protective, marine, and container coatings for heavy-duty asset protection.

- Jotun A/S: Provides protective, marine, and decorative coatings, known for durability in harsh conditions.

- Nippon Paint Holdings Co., Ltd.: Offers automotive, industrial, and decorative liquid coatings with a strong Asian presence.

- RPM International Inc.: Diversified specialty chemical company providing protective coatings and sealants for industrial markets.

More Insights in Towards Chemical and Materials:

- Automotive Paints & Coatings Market Size to Hit USD 48.22 Bn by 2035

- Water-Based Solvent Paints Market Size to Surpass USD 153.39 Bn by 2035

- Paints and Coatings Market Size to Hit USD 348.04 Bn by 2034

- European Paints & Coatings Market Size to Hit USD 54.27 Bn by 2034

- U.S. Paints & Coatings Market Size to Reach USD 50.23 Billion by 2034

- Cement Paints Market Hits USD 8.11 Bn at 3.25% CAGR [2025-34]

- Waterborne Coatings Market Size to Surpass USD 166.38 Bn by 2035

- Industrial Coatings Market Size to Hit USD 176.06 Bn by 2035

- Biopolymer Coatings Market Size to Reach USD 109.08 Bn by 2035

- U.S. Conformal Coatings Market Size to Surge USD 3.16 Billion by 2034

- U.S. Powder Coatings Market Size to Hit USD 11.65 Billion by 2034

- U.S. Mirror Coatings Market Size to Surge USD 304.83 Million by 2034

- European Paints & Coatings Market Size to Hit USD 54.27 Bn by 2034

- U.S. Industrial Coatings Market Size to Hit USD 38.81 Bn by 2034

- Sustained Release Coatings Market Size to Hit USD 1,373.63 Mn by 2034

- U.S. Paints & Coatings Market Size to Reach USD 50.23 Billion by 2034

- Low-VOC Coatings Market Size to Reach USD 15.16 Billion by 2034

- Functional Coatings Market Volume to Hit 13.14 Million Tons by 2034

- U.S. Diamond Coatings Market Volume to Reach 945.31 Kilo Tons by 2034

- Wood Coatings Market Size to Worth Around USD 20.36 Bn by 2034

- Green Coatings Market Size to Surpass USD 145.19 Billion by 2035

- Powder Coatings Market: Demand, Production, and Future Projections

- Concrete Floor Coatings Market Size Leads USD 8.53 Bn By 2034

- Flat Glass Coatings Market Size to Hit USD 14.75 Billion by 2034

- Pipe Coatings Market Leads USD 16.84 Bn at 5.40% CAGR

- Nanocoatings Market Size and Forecast 2025 to 2034

-

Self-Healing Coatings Market Leads USD 39.16 Bn at 28.42% CAGR

Liquid Paints and Coatings Market Top Key Companies:

- Asian Paints

- Axalta Coating Systems

- BASF SE

- Akzo Nobel N.V.

- The Sherwin-Williams Company

- PPG Industries, Inc

- Hempel A/S

- Jotun A/S

- Nippon Paint Holdings Co., Ltd.

- RPM International Inc.

Recent Developments

-

In November 2025, LyondellBsell (LYB) and Nippon Paint China announced a collaboration at the China International Import Expo to create a closed-loop recycling systems for coating packaging barrels, aiming to mechanically recycled used containers into new materials. This initiative supports circularity in coatings packaging and reduces reliance on virgin plastics.

Liquid Paints and Coatings Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2035. For this study, Towards Chemical and Materials has segmented the global Liquid Paints and Coatings Market

By Type

- Solvent-based

- Water-based

- UV-curable

- High-solid coatings

- Powder-in-liquid hybrids (emerging tech)

By Resin Type

- Acrylic

- Epoxy

- Polyurethane

- Polyester

- Alkyd

- Vinyl & Others

By Application

- Building & Construction

- Automotive & Transportation

- Industrial Equipment

- Wood & Furniture

- Packaging

- Marine

- Aerospace

- Consumer Goods (appliances, electronics)

By Substrate

- Metal

- Wood

- Plastic

- Concrete

- Glass

- Composites

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@https://www.towardschemandmaterials.com/checkout/6062

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics | TCM Blog

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.